|

Homemade Bikes: the progress report..

last edited may '03

This is a very simplistic page, obviously. I got asked by some folks on the framebuilder's list to post some pictures back when I was working on the frame, and this is what I put together. It is decidedly non-exhaustive, but should be helpful to those who are completely newbies, such as myself when I started. I can only assume that it's interesting to somebody because it consistently gets browsed a few dozen times a month. Apologies for the long pages with lots of pictures. I'm afraid I just don't have the time to go back and split up everything nicely. Find some good music to listen to while the page loads if you're still working with a dial-up connection (that makes two of us..)

The tubeset, from Bringheli's. I originally planned to build using straight guage aircraft CrMo. However, Bringheli's was getting rid of a few of these low-end tubesets, someone tipped me off, and I landed this bike for 42 dollars, shipped, IIRC. It is Dedacciai Zero Tre, steel. The main triangle is butted, the rear is tapered. Quite nice, really.

ok. i dont want to hear it, you dang purists ;)

yes, i bought the fork, and yes, it is carbon. any RBTers here? dont tell them i like carbon. anyways, my reasons were as follows: First, building the fork seemed sort of boring. the crown is ready to go. the steerer is the right size. the only two variables that matter are length and rake. i preferred to spend my time on the frame. second, i love the look of carbon. the curved aesthetics delight me, as does being able to see the structural fibers inside (and yes, i know that top layer of fiber is cosmetic, but hang with me here..). third, itd be a shame if the fork failed, and i want to spend more time working on my welding than my brazing. forks also sound like they are less tolerant of alignment and construction error. last, i got a sweet deal. this has a steel steerer (i coudl care less abotu the weight), clearance for 28c, and cost me 60 dollars. and dont even tell me it isnt beautiful. i have a stem abotu the right length in threadless, and i think threadless looks better anyway (oh, please dont let rbt in on this..) so im going threadless. and thats that.

i planned the bike out on plotter paper borrowed from the architecture building. they didnt need it anyway. the camera doesnt let you see much, but ive jacked up the contrast so at least some lines come through. this is the first sketch. to lay the bike out, i put the bb and axle lines in, with my chosen BB drop (58mm). i then picked a seat tube angle, 73, which i heard 'always worked', and went up 54 cm, which gave me a standover clearance that worked, and my current bike is 54 c-c and fits great. i then, staying parallel to the axle axis, drew in the top tube 56 cm c-c. this is a little longer than normal, but i did it becuase i dont mind stretching out, and i do mind getting smooshed up in the cockpit, and it would give me more toe overlap room. i then drew in the ht axis at 74.5 degrees. i wanted steep track handling. as i said before, this bike is meant to be a slow speed having fun very twitchy very maneuverably playbike. we'll see what happens. i had previously measured the fork for rake and length. i drew the fork in, and marked how long the headtube woudl have to be, with room for a headset (threadless cheap aheadset).

after all this, i measured my own bike to estimate toe overlap. i use 165 mm cranks (for spinning my fixed gear and cornering clearance), and by my best estimate, my cycling shoes extend 100 mm beyond the pedal spindle. i drew in arcs for my toe, and for the wheel. there was too much overlap (yes, i eventually figured out that because the cranks are out to the side the overlap is exaggerated on paper, but it was still too much). i would tolerate no overlap at all, and actually wanted to make it with clearance to spare so that if my calculations were wrong, i woudlnthit my toe. i love trackstanding, and not having to think about about tapping my wheel with my toe, which frankly sucks the big one if all you want to do is move around slowly in little circles. (maybe i should have gotten a skateboard instead of buildign a bike). anyways, i remedied this by moving the BB backwards by choosing steeper ST angles. i looked at track bike geometries from a variety of companies, and it looked like they had some steep ST angles, so it could work fine, i imagined. the many lines in the drawing are my sketches for 74 and then 75 degree seat tubes, until i got the clearance i wanted.

these were sketches to get an idea of waht angles the chainstays and seat stays woudl be at, as well as the minimal chainstay length i could get away with. i wanted as short a wheelbase as possible, with the ability to get the wheel into the horizontal drops. i didnt much care about having to deflate the wheel to get it in because the only reason i will ever take the wheel off is to fix a flat, and itd be deflated anyway. however, i wasnt willing to cut it that close, in case i mess something up, and then coudlnt get the wheel into the bike whether the whel was deflated or not . (although in this case, i guess i could shorten the bottom side of the dropout as a worst-case hack job)

I wanted horizontal road dropouts. I am building this bike to be a fixed gear play-bike. It will never have a derailleur, nor a rear brake, nor a rack, nor a.. (etc) so i didnt need any eyelets, braze-ons, all that jazz. These dropouts are forged steel from the QBP catalog. My LBS cut me what I believe is a solid deal and I got these for nine dollars. No shipping. I originally thought of machining my own from plate, but for nine dollars I couldnt refuse. As you can see here, I ground the eyelets off, as well as the derailleur hanger, and cleaned things up a bit. These dropouts do not have a hole drilled for adjuster screws, which is a plus. They did have a reinforced section at that part of the drop to drill your own, i imagine, so i took the liberty of filing that out so there is a raised curve all the way around. These will eventually be brazed in.

The tubes: i sprayed the main tubes with a metal dye, and scratched a line along the length. This served as my reference until the front triangle was welded. I did this by clamping the tubes in a v-block, and scoring with a vernier height guage, but it doesnt have to be so prissy. I did all my work in a fabrication lab on campus, and the fellow who has been helping me out is a machinist, so it has been funny using all these 0.001" tolerance bits and pieces for a bike. Aside: it has been a good call, thus far. In this picture, I am actually scoring a second line on the DT. this is becuase the first line was a reference for the HT miter, and now i need to score a line for the DT miter which is in the perpendicular plane. My method was pretty nifty, but you could also do this with a piece of paper and a ruler, and sacrifise that 0.005" tolerance. ;)

I knew how to MIG before I got it into my head to build a bike. I also knew how to TIG, but had only practised for a half hour or so. Just long enough to know it was tricky. The first few months of working on the bike were actually more materials practise than actually working on the bike. This pile of junk are my practise welds, with the ancient but beautiful TIG welder in the chemistry metal shop. The metal is largely shitty steel alloy tubing from floor lamps that people throw out on campus every week. It was nice to work with because it was so soft and mitered like you were cutting butter.

When i boguht the tubeset, i didnt really know what i was doing. I still know very little, but have learned that one wants a thicker head tube than what i have. HT ring reinforcements are apparnetly the way to go, so i cut a couple out of some junked mountain bike, slotted them, bent them by hand to size, and silver soldered them to tubes to practise for the real thing. Here, you can see my amateur brazing job. The first one was tacked welded in place to hold it. The second one I bent into a smaller radius so it held onto the tube on its own. I think I got one of them too hot. However, I think soldering (is that the right term?) on the real bike will be easier because there is more metal to act as a heat sink. Just in case that isn't enough, I have machined a copper heatsink which slip-fits into the HT, which I hope will buffer the metal temperature when I finally put these rings on.

I've been using a milling machine to miter the front triangle, and I now regret it. It took me a while to make the tube blocks solid enough to get clamped in the milling vice. Then every time I mitered a tube I had to set the machine up for that particular angle which is a pain. And every time I finished I had to reset the machine and sweep the table with an indicator to check it was vertical again. And if all that wasn't annoying enough, I managed to destroy a few mill-jobs, folding the fish-mouth in on itself. I mitered with four-fluted end mills, which were reasonably sharp, but not amazingly sharp. I had to grind some of them myself, so even if they were sharp, sometimes one flute was a tiny bit taller than another, and i had to go extra slow. The tubes needed to be reinforced from the inside to avoid the tube-folding, which I found out the hard way. (i didnt think it woudl happen because all my practise miters on soft steel didnt.. but i shoudl have guessed).

After I folded one tube i cut up a board of maple, lathed it down to a fairly tight fit that i could push in with some hand pressure, and tried again. worried that the end mill would push the wood into the tube, i tried to reinforce it from behind with a metal rod pushing from the other end of the tube. this turned out to be practically impossible (not impossible, but a pain.). so i tried milling the tube with my tight-fit wood plugs, and everything was going just fine. It bears mentioning how I was milling- in the beginning, with the soft steel, i would just lower the end mill to the level of the tube, and bring it on from the side. however, this didnt seem to be as nice for the hard crmo tubeset, so i ended up doing something different: I would keep the end mill above the work, and bring it down with the quill (like a drill press) to chew off a millimeter or two of metal (while applying copious amounts of cutting oil), bring it back up, advance the tube a fraction of an inch, and go down again. it was hairy as heck, and on that last pass the damn tube folded up again, pushing my wood plug into the tube.

Pissed off, becuase I now had to shorten my desired top tube length to compensate, I proceeded to lathe myself a new version of tube plugs. Maple, becuase its hard wood, and i made them oversize. I then took them over to the belt sander, and made them an extremely (read: no way you could get them in by hand) tight fit. i tapered them one end a little bit to start myself off, and then hammered them in by whacking the tube/plug on the concrete floor until the plug was just short of flush with the tube. So far- no bent tubes with this method, though i was still very careful. For future reference, it took me ten as-hard-as-i-can over-my-head whacks to get the plugs in, and it actually flared the outside diameter of the tubes a few thousands of an inch. No, i dont think this is in my imagination, i checked with a caliper. After the milling, I would get them out wiht a slide hammer (read: long rod of something heavy, and a lot of whacking)

Anyways, next time i will use a file. I ended up using a file to put the second miter in the bottom of my downtube, and i had no idea it was so easy and clean. There is obviously a lot i dont know about milling these tubes, but filing woudl have been perfect for me becuase a) its slow and i am new and there are lots of oporutnities to stop and make sure i am doing the right thing. b) you can not rip or bend a tube with a file c) the way i was milling, it is pretty much just as fast to file in terms of removing material d) the tube blocks dont need to be as hardcore, i could have made them out of wood (maybe i coudl have done this anyway, but..) e) did i mention no bent and ripped miters? f) this is a one-off job. i never had to do the same miter twice, so there was no point in all the set up time for the milling machine (finding edges of tube, zeroing digital readout, getting everythign dialed in, blah blah blah.

A picture of my tube blocks, as well as some wooden plugs after they've been taken out of the tubes. The tube blocks were made in two ways. One way was ridiculous, difficult, and slow. The other was easy. THe first tube block I made was the long 1" diamter one (only one side shown). this was to hold the floor lamp tubing for practise miters. i did it by using a 1" ball end mill and cutting pass after pass in both blocks until i had almost a full semi-circle. It took forever. ball end mills dont cut well, and it was a damn waste of time if i ever saw one. The second and third tube blocks I did by sandwhiching two pieces of aluminum together, and then drilling the correct size hole. I would then machine away a 1/16" or so off the top. If i were to do it again, i would make these tube blocks much longer. these are 2" long or so, and are anoying to work with, and very likely less accurate (for milling) then longer blocks. Next time..

after milling, the tubes still needed a lot of work. (hey, did i mention that milling was a wasteof my time?). for some tubes i needed to bring the diameter out to the correct radius (for instance, my BB is 1.535" and the closest end mill is 1.5"). This was done by file. I also needed to clean up the miters which had large wings of metal where the end mill had pushed metal away from the tube instead of cutting it off. this was done largely by hand on the belt sander, with care, and clean up done with a deburring tool and a file.

the finished front triangle miters. this bike will hopefully be a 74.5 HT, 75 ST playbike. the downtube has been mitered off center to sit tangent to the bottom bracket, which looks nice, although Im not sure it was worth the trouble. in the head tube are my dummy headset pieces, which i machined fro aluminum. I am not cutting the seat tube down yet, as i can always do it later, and for now it doesnt bother me tall. I figure that extra metal could act as a heat sink, and also- my seat post will go well above that tube, so why not leave it long, cut the seat post short, and save weight? Maybe there is something I dont know. If there is a lot of weld oxidation on the inside of the tube, or bead drop through, i imagine i will have to cut the seat tube down to normal proportions so that it can be reamed without sticking 8" of tooling into the tube. Then again, maybe thats fine. I'll see when I get there.

my front triangle jig is a piece of 3/4" particle board with the plastic coating on both sides you see on kitchen counters. I picked it becuase it is very flat, with a bow of about a half millimeter or so in the middle, which gentle pressure takes out. I took my drawing, which had been my reference fro all the miter-to-miter lengths, spray-adhesive glued it to the board, and used a couple machinist's squares to place aluminum angles in the right places. In each Al angle, I drilled two holes that were oversize for the screws, which left me a little wiggle room to precisely line them up with the drawing. I also machined myself a set of tube risers to keep each tube at its correct height off the table surface. The tubes sit on these risers, against the angle, and are held down by quick-and-dirty springs i made out of strips of aluminum, bent, with a fat wood screw near the bottom. the only one that is engaged right now is on the HT. when the tubes are in place, these springs (two per tube except for the HT) press down ont eh tubes at a roughly 45 degree angle, which keeps them aagainst the risers and angle. These springs are easy to work with, and swivel out of the way for easy in/out, but are not that strong. I was just hoping that the metal would not warp beccause these springs would not hold anythign back, but it turned out fine.

close-up of the springs.

the whole jig. when they are all tightened down, they are actually quite strong. I just don't think they are strong enough to resist warping metal, but actually- im not sure how much force that actually exerts.

close up of the tube blocks, and my dummy headset. the lower stack spacer had to have weird inner diameters machined into it to clear the aluminum race-area bits around the fork. the top bit has three allen set screws to hold it in, on center. maybe that was a little overkill. one woudl probably do.

the welded front triangle. my welding sequence was as follows. I did my

best to back-purge the welds with argon. I used a 1/16" 2% thorium

electrode with 702-s copper plated rod, in the next size down from 1/16",

whatever that is. first off, i welded the ST to the BB completely around

the miter. I did this by clamping the two in the jig, tacking and welding

and moving it around as necessary. When i was sure it was true

(perpendicular), I jigged it with the rest of the front triangle, and

tacked each joint on each side. I then tacked the top of the tubes.

Throughout this, i kept checking to see if all was sitting pretty in the

jig. It was throughout, so i kept going. After three, and sometimes four

tacks in the jig, I took the tubes out, and tacked the backside. I then

re-jigged it (still checking alignment in the jig all the time) and welded

the same way i had tacked- side, other side, then top. then i took it out

of the jig, welded the backside, and filled in all the gaps between beads

that i had left. (each joint was not four beads. it was more like eight.

for the record, it turns out that i coudl use some more practise in TIG.

in the damn practise samples, I could get a pretty bead around the whole

tube. in normal welding, like with thicker metals, or straight beads, dont

even get me started.. so much easier.. but as soon as I started on the

real bike, i just got really nervous

and started dipping the electrode left and right, and generally making a

mess of things. The welds, after a lot of frustration, are fine, but good

lawd- they dont look like merlin's. Im hoping that a) the paint covers it

up a

little, and b) no one who actually knows how to weld sees these joints up

close. anyways, i suppose theyre not all that bad in the general scheme

of things. since finishing this bike, and seeing some other amateur

builders, and undergrad weldors at work, maybe i did pretty well,

relatively speaking.

i am just frustrated that i couldnt get pretty seamless fishscales

the whole way round the tubes, and had to starta dn stop all the

time.

it bears mentioning that although i used a thin filler rod for

most of the triangle, i used 1/16" for the inside beads of the BB. this was because i was having trouble getting enough filler rod in and melted through (small hole.. i promise). however, i was lazy and did not turn the amperage up after that, and got a fat blocky bead around the inside edges. To take care of this, partially, I did a second pass with the TIG torch, washing over the bead with no filler. Still, it doesnt look that hot. Can you tell I'm not pro yet? I dont feel so bad when i think about the fact that I actually only have a minimal amount of actual welding time under my belt. Remember those samples in the picture further up? That's it. It's amazing how hard miters and tight corners with no torch clearance are compared to just welding straight edges together. ah well.

another picture. you can see here the BB clamp. To hold the BB down in the jig, I machined a disc of aluminum to the tightest fit i could get to slip into the threads. I then bolted through the particle board (countersinking the back so it didnt warp the surface) onto this disc. then, i made a cone that slipped down over the 1/4" bolt, and could get tightened down. this held my BB perpendicular to the table, unable to move in any directions, and with the surface as a height reference.

close up of BB. these welds don't look so hot, but hey, whatcha' gonna do? actually, you can see the BB clamp better in this picture. the cone is on top of the disc, with a nut at the top of the bolt. when i machined that disc (basically, a bushing, if that is the correct word) i measured the inside of the RH threads and machined to that spec. but it didnt fit! did you know the LH threads have a smaller ID than the RH? maybe it was just this BB.

close up of HT. i worried about whether the TIG would warp the tube. it did, but not by more than a couple 0.001's or so. the dummy headset i made was a tight fit already, and i can still pop it in, though with a firm push and a twist instead of a firm push. (very exact science, here). Actually, now that i think about it, the difficulty in getting the dummy headset in might be the weld oxidation inside the tube, not tube warp. but whatever. the wood blocks are what i rest my arms on while im welding.

to check how straight the front triangle ended up, i put it on a surface table with the riser blocks (they are all +/- 0.003"). The head tube and seat tube are in the same plane (i cant rock the frame), and the top tube is perfect. the BB is flat against the table. the downtube seems to be a few thousands off center, but this shouldnt really matter, both in function and with scale considered.

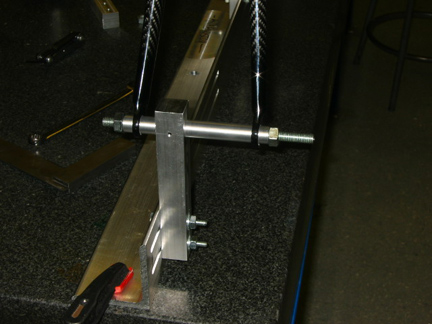

the rear jig is made out of a section of 3" aluminum angle. if i were to do it again, i would pick a much beefier thickness that would flex less, and possibly be more accurate. i machined slots into the area the dummy axles would go, so i could use this jig again, and bolted a clamp to hold the BB. i attached it to a surface plate with two clamps, and it seems to be sturdy as necessary. the front dummy axle has a riser to the correct height for BB drop, and uses 3/8" threaded rod for the axle. there is a set screw holding the axle from moving, and i machined spacers to center the 100mm spaced fork, on center with the BB. my two references for the jig are the top of the angle, and the side that faces out. whenever i bolted to it, like these risers, i machined them flat so as to keep the angle flat as a reference (which is act ually a little wavy, but machining the whole thing was beyond my patience).

the back axle is the same thing, with wing nuts, and 120 mm spacing (track hub spacing, i hope). the wing nuts are becuase i will need to move the dropouts in and out more frequently than the front fork, which will just get clamped and stay there. theyd be nice for the front too, but the metal supplier in the central campus lab only had two.

the rear BB clamp. it is machined so that it is like an extension of the face fo the angle on the outside. the inner side of the Al angle was not flat, as it got thicker towards the middle, so i rigged a fly cutter on a milling machined to put a flat in relative to the reference face. opriginally, i had hoped to bolt the BB to the Al angle itself, but then i realized that the right chainstay woudl be impossible to mount. whoops. for this i had to make taller axle risers and make that BB plate.

close up of the BB clamp. spacer (fits tightly into the threads to make sure BB is centered), is bolted to jig. then a cone tightens down on other side.

the clamp in action.

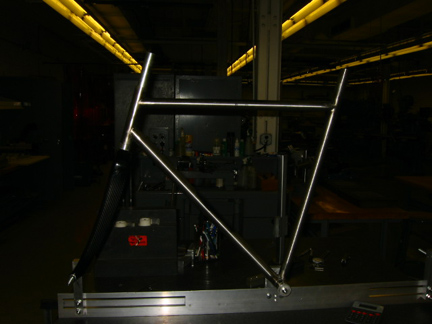

the whole kit and caboodle. front fork and dummy headset, in the jig. bad lighting, sorry. it turns out that the jig's aluminum angle is not exactly 90 degrees. over 3" it looked good, but now that i have the risers (8" high or so) and the dummy axles sticking out all over the place, i can see that the whole angle is slightly less than 90 degrees. because the two dummy axles are off by the same angle, i will assume that the entire angle is teh same, and will therefore not result in misalignment. knock on wood.

|